News & Updates

Insights from the frontlines of on-demand manufacturing.

Here we share highlights from On Demand 2033 – including events, collaborations, and lessons learned from the project. Most of our updates are currently published in Swedish. Want to dive deeper?

Formnext 2025: Four Insights Shaping the Future of On-Demand Manufacturing

An analysis from the perspective of On Demand 2033

Formnext 2025 reveals an industry in transition – technically mature, commercially searching, and systemically unfinished. For On Demand 2033, this year’s fair confirms that the technological building blocks are in place, but that the real transformation now depends on the system dimensions surrounding them.

Despite record attendance and impressive technical launches, it is clear that Europe still lacks the business models, competencies and structures required to scale additive manufacturing industrially. This year’s observations therefore extend far beyond machines – they describe an ecosystem still looking for direction, yet increasingly interested in the solutions our project is developing.

Below are four key observations from the fair, structured according to On Demand 2033’s system dimensions.

1. Technology is ready – but business models are not

Across the exhibition floor, a wide range of mature technologies was on display: advanced PBF systems, specialised e-beam solutions, robust DED platforms, and innovative sintering approaches. What was missing, however, were discussions about how these technologies are meant to create profitability.

Exhibitors described difficulties breaking into existing value chains, securing willingness to pay, and formulating attractive offerings. Europe’s lack of a unified AM strategy contributes to a fragmented market – different actors build their own logic, which fails to connect.

For On Demand 2033, this is a direct confirmation: the potential of AM is only realised when it is paired with new business models that support digital inventories, spare-part production, service-based offerings and distributed manufacturing.

2. Competence, culture and mindset remain the biggest barriers

Despite a growing number of Nordic exhibitors and more industrial cases, the organisational capability to implement AM in a structured way is still often missing.

The same questions returned repeatedly – on stage and in meeting rooms:

- How do we qualify parts?

- How do we build internal competence rather than isolated pilots?

- How do we shift procurement logic and design philosophy?

The technology is advancing – but organisations are not keeping pace. Cultural inertia across Europe was a recurring theme, and several international actors expressed interest in On Demand 2033 precisely because the project tackles the competence-related system challenge.

3. The role of digitalisation is becoming clearer – but the infrastructure is not there yet

Scanning, digital inventories, traceability, qualification and distributed manufacturing are now mentioned in every strategic conversation. At the same time, it is evident that the digital components of the ecosystem are unevenly developed.

Examples from our meetings illustrate that:

- Several industrial companies want to explore distributed manufacturing but lack secure workflows

- OEMs are experimenting with digital inventories but miss long-term processes and transparency

- Universities and research environments are seeking collaboration on demonstration cases

- International actors are actively looking for Swedish partners to build digital infrastructure

The digital shift is therefore not a technological shift – but a process and system shift. This is precisely where the focus areas of On Demand 2033 are well-timed.

4. Collaboration is not optional – it is a prerequisite

A recurring theme in discussions was Europe’s fragmentation. Machine manufacturers, material suppliers, industrial companies and research institutions operate increasingly in silos. The contrast to the US and China — where national strategies drive development – is clear.

At the same time, the willingness to collaborate is strong. Contacts from Finland, Norway, Germany, Spain, Bulgaria, Australia and Sweden expressed the same needs: to work together on cases, standards, education and new ways of organising production.

For On Demand 2033, this means that our role as a shared arena becomes even more important. What is being asked for is not only technology – but coordination, methodology and structures that enable scale.

Conclusion: The shift happens in the system – not in the machines

Formnext 2025 shows an industry on the verge of its next major step. The machines are ready. The materials are available. Cases are emerging everywhere. But industrialisation is not hindered by technology – it is hindered by business models, culture, competence, digital infrastructure and collaboration.

In other words: exactly the system dimensions that On Demand 2033 is working to develop.

We leave this year’s fair with strengthened international relationships, concrete pathways for new cases, and a clear confirmation that Sweden has an important role to play in Europe’s work to build resilient, local and sustainable manufacturing for the future.

The work continues – and accelerates.

From aluminum to polymer – a strategic material switch

Three key lessons from an AM case – on material choices, smart design and transparency

As part of the On Demand 2033 initiative, a new method for producing a spare part using additive manufacturing (AM) was recently tested. The results show the potential of the technology – in terms of sustainability, cost, and future business models.

The component in question is currently made of aluminum and sold with a healthy margin. In the project, a new version was manufactured using the polymer PA12, printed by AM Printservice. The material was chosen for its strength, workability, and low climate impact.

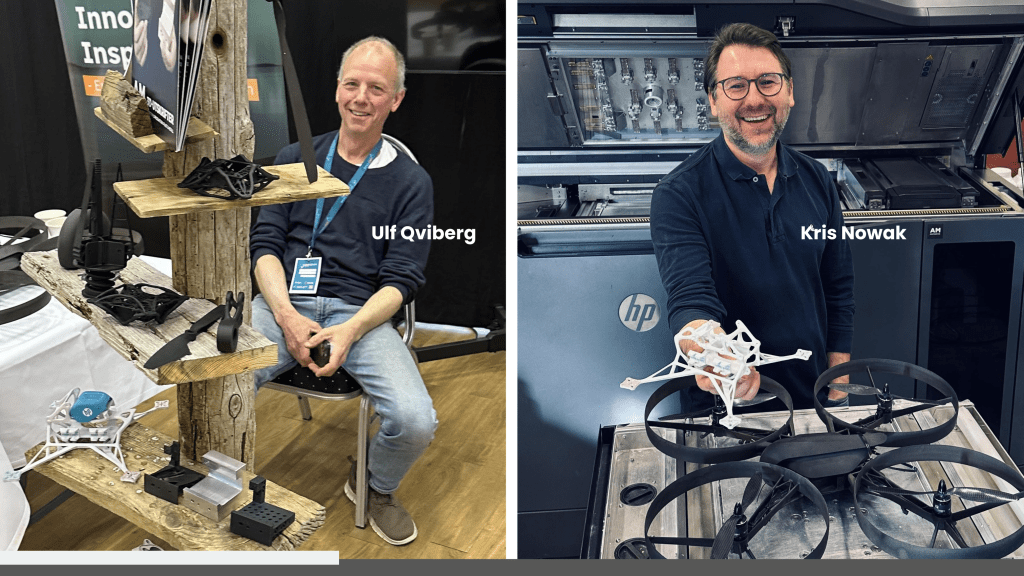

AM Printservice, based in Västervik, specializes in additive manufacturing in both plastics and metals. They provide everything from prototypes and spare parts to series production and digital inventory solutions. Using technologies like HP Multi Jet Fusion, they produce components in PA12, PA11 and TPU – and in metal via partners. A key part of their work is helping industry identify suitable parts for 3D printing and supporting the transition to more sustainable and cost-effective solutions.

“Metal is often used out of habit – not necessity. Switching to plastic often means lower weight and cost, without sacrificing function,” says Krzysztof Nowak, COO at AM Printservice.

Printed – at a fraction of the cost

The new version was created by scanning the original part and converting it into a printable 3D model. The printed version cost just 250–360 SEK, depending on volume – compared to several thousand for the original.

And that was just the beginning.

“This is a textbook case of the three-step approach: First, switch materials. Then print the current design. Finally, optimize the design for even better function and lower cost,” says Ulf Qviberg, CEO at AM Printservice.

Business models – just as important as technology

Despite the technical success, the original manufacturer chose not to move forward, and no real-life testing was conducted. But that doesn’t make the case less valuable – quite the opposite.

“We see this as a key learning case. It highlights the barriers new technologies may face – but also the vast potential if more players are willing to challenge old structures,” says Nicklas Tarantino from On Demand 2033.

Measurable climate

AM Printservice is also part of an ongoing LCA study together with EIT, comparing their AM method with conventional production.

“We reuse up to 80% of the material, generate virtually no waste, and don’t need cooling or water. Plus, production is local – meaning shorter transport,” explains Krzysztof Nowak.

The results, to be published soon, suggest clear environmental benefits of AM – especially for low-volume parts and spare components. This could be a game-changer for companies considering the shift.

Ask better questions – get better results

One key insight: many companies ask the wrong questions.

“It’s not about if 3D printing works – but about what you want to achieve. Lower cost? Shorter lead time? Fewer parts to assemble? Once you ask the right questions, 3D printing often becomes the right answer,” says Krzysztof Nowak.

Another common misconception is that you need to invest in your own machine to get started.

“That’s a big leap – in both cost and competence. That’s where service providers like us come in. You don’t need a printer, staff or training – just an idea,” adds Ulf Qviberg.

Part of a bigger mission

This is one of several demonstration cases within On Demand 2033 – a national initiative exploring how Sweden can build a more resilient, competitive, and sustainable industry through local, digital, and on-demand production.

In this case, no implementation followed. But the insights remain – and open the door for others curious about new production methods.

“We believe in sharing real-world examples. Not all cases succeed right away – but each one helps us move forward,” concludes Nicklas Tarantino.

This case clearly shows that even when AM solutions aren’t adopted immediately, valuable lessons are gained – helping move industry closer to more sustainable production.

Where tradition meets innovation – 3D printing in the forests of Värmland

A legacy of precision – now powered by AM

Here’s another real-world case from the On Demand 2033 initiative, where Norma, located in Åmotfors, has taken a step into the future – with the help of additive manufacturing.

In Åmotfors, nestled deep in the Värmland forests, Norma has been producing ammunition since 1902. With over a century of craftsmanship, precision, and quality, the company is a trusted name among hunters and sport shooters worldwide. But it’s not just tradition that drives Norma forward.

On the factory floor, a quiet but powerful transformation is underway – powered by 3D printing.

It’s not about printing ammunition. It’s about using additive manufacturing to produce molds, tools, and fixtures used in the production process – a modern solution proving to be both time- and cost-efficient. And the best part? It started organically, from within.

“I first saw the need back in 2017,” says Patric Crafoord, mechanical designer at Norma. “We had components that were difficult to mill, time-consuming and required several setups. We tested printing parts like grippers, templates and holders with an FDM printer – and instantly saved time and money.”

Visual tools made faster and cheaper

One of the first components to be 3D printed were champlunes – visual measuring tools that ensure projectile shape and quality. Since then, the technology has spread across Norma’s production line.

“Today, we’re evaluating different materials and techniques for a type of gripper we currently import from Switzerland,” says Christian Albinsson, machine designer. “We expect to reduce the cost to a tenth, and eliminate long delivery times – which supports further investment in 3D printers.”

A key success factor: genuine interest

The reason it works so well? It’s not just technology – it’s passion.

“Both Christian and I were personally interested in 3D printing long before we started using it at work,” says Patric. “That helped us push the development internally, and the technology has grown naturally from there.”

Christian adds:

“We’re seeing increasing usage. The new printer we bought runs 24/7 – and we’re already planning to invest in more. It clearly fills a real need.”

And there’s plenty of need to go around. With over 150 different cartridge cases and 70 bullet types in various calibers, Norma’s product range is wide. 3D printing enables rapid development of support tools and molds – without waiting for external suppliers.

“We can redesign a component and have it ready for testing in half an hour. That used to take days,” says Patric.

Not a replacement – but a powerful

Despite the many benefits, 3D printing is not replacing traditional methods like CNC machining – it’s complementing them.

“Milling and turning still have their place. It’s about choosing the right tool for the right task,” says Patric.

For Norma, additive manufacturing has already led to real progress. The next step is to spread the knowledge throughout the organization and continue exploring new materials and techniques – such as SLA and SLS – to meet the demands of the future.

“We’ll likely see a shift in how we organize this work. Today, it’s handled by us designers. In the future, it may become part of the tooling department,” says Christian.

Precision powered by progress

There’s something remarkable about companies that manage to innovate without losing their soul. At Norma, this transformation is in full swing – where more than 100 years of engineering meets modern additive manufacturing.

It’s a shining example of how tradition and innovation can go hand in hand – with precision.

Want more stories?

Explore more news

We regularly publish updates, case studies and insights – straight from the frontline of additive manufacturing in Sweden.